Cov ntaub tsis yog woven(NonWovenFabric) yog ib hom ntaub uas tsis tas yuav tig thiab ntaub. Nws tsuas yog tsim los ntawm kev txhawb nqa lossis kev txhawb nqa random ntawm cov fiber luv luv lossis filament los tsim cov qauv fiber network, thiab tom qab ntawd txhawb nqa los ntawm kev siv tshuab, thermal bonding lossis tshuaj lom neeg.

Hais yooj yim xwb, nws tsis yog ua los ntawm cov xov uas raug xov thiab xaws ua ke, tab sis cov xov raug sib txuas ua ke ncaj qha los ntawm lub cev, yog li thaum koj tau txais cov kua nplaum hauv koj cov khaub ncaws, koj yuav pom tias tsis muaj xov yuav tsum rub tawm.

Cov yam ntxwv ntawm cov ntaub tsis-woven

Cov ntaub tsis-woven tsis muaj warp thiab weft, thiab yooj yim txiav thiab xaws, thiab yog lub teeb thiab yooj yim rau cov duab. Nonwovens tawg los ntawm cov ntsiab cai textile ib txwm muaj, thiab muaj cov yam ntxwv ntawm cov txheej txheem luv luv, cov nqi tsim khoom sai, cov txiaj ntsig siab, tus nqi qis, kev siv dav thiab ntau qhov chaw ntawm cov khoom siv raw.

Spunlace Nonwoven Npuag Rau Cov Ntaub So Ntub Dej

Cov txiaj ntsig:

lub teeb

Nrog polypropylene resin ua cov khoom siv raw tseem ceeb, qhov hnyav tshwj xeeb tsuas yog 0.9, tsuas yog peb feem tsib ntawm paj rwb, fluffy, xav tias zoo.

mos mos

Ua los ntawm cov fibers zoo (2-3D) lub teeb taw tes kub yaj molding. Cov khoom yog mos thiab xis nyob.

Kev nqus dej, cua nkag

Daim polypropylene tsis nqus dej, cov dej noo yog xoom, cov khoom tiav lawm zoo ntawm dej, nws yog tsim los ntawm 100% fiber nrog porosity zoo thiab cua permeability, yooj yim kom daim ntaub qhuav thiab yooj yim ntxuav.

Tsis muaj tshuaj lom thiab tsis khaus

Cov khoom no yog ua los ntawm cov khoom noj khoom haus raws li FDA, tsis muaj lwm yam khoom xyaw tshuaj lom neeg, kev ua haujlwm ruaj khov, tsis muaj tshuaj lom, tsis muaj ntxhiab, thiab tsis ua rau daim tawv nqaij khaus.

tshuaj tua kab mob

Polypropylene yog cov khoom siv tshuaj lom neeg, tsis yog npauj npaim, thiab tuaj yeem cais tawm qhov muaj cov kab mob kua thiab cov kab yaig.

Cov khoom tua kab mob

Cov khoom uas muaj dej, tsis yog pwm, thiab tuaj yeem cais tawm qhov muaj cov kab mob kua thiab cov kab yaig, tsis yog npauj npaim pwm.

Cov khoom zoo ntawm lub cev

Los ntawm polypropylene spinning ncaj qha mus rau hauv lub network ntawm thermal bonding, cov khoom muaj zog zoo dua li cov khoom siv fiber ntau, lub zog tsis muaj kev taw qhia, ntsug thiab kab rov tav lub zog zoo sib xws.

Kev tiv thaiv ib puag ncig

Hais txog kev tiv thaiv ib puag ncig, cov khoom siv raw ntawm feem ntau cov ntaub tsis-woven siv yog polypropylene, thaum cov khoom siv raw ntawm cov hnab yas yog polyethylene. Txawm hais tias ob yam khoom muaj lub npe zoo sib xws, lawv txawv heev hauv cov qauv tshuaj lom neeg. Cov qauv tshuaj lom neeg ntawm polyethylene ruaj khov heev thiab nyuaj rau degrade, yog li nws siv sijhawm 300 xyoo rau cov hnab yas kom decompose. Cov qauv tshuaj lom neeg ntawm polypropylene tsis ruaj khov, cov saw hlau molecular tuaj yeem tawg yooj yim, yog li nws tuaj yeem decompose tau zoo, thiab hauv daim ntawv tsis muaj tshuaj lom rau hauv lub voj voog ib puag ncig tom ntej, lub hnab khw tsis-woven hauv 90 hnub tuaj yeem decompose tag nrho. Ntxiv mus, lub hnab khw tsis-woven tuaj yeem rov siv dua ntau dua 10 zaug, thiab nws cov pa phem rau ib puag ncig tom qab pov tseg tsuas yog 10% ntawm cov hnab yas.

Cov Khoom Siv Uas Tsis Yog Npuag Uas Tsis Muaj Xov

Qhov Tsis Zoo:

Piv nrog rau cov ntaub textile, nws lub zog thiab kev ua haujlwm tsis zoo.

Nws tsis tuaj yeem ntxuav tau zoo li lwm cov ntaub.

Cov fibers tau teeb tsa rau hauv ib qho kev taw qhia, yog li lawv feem ntau faib ntawm cov ces kaum sab xis, thiab lwm yam. Yog li ntawd, kev txhim kho ntawm cov txheej txheem tsim khoom feem ntau yog nyob rau ntawm kev txhim kho ntawm kev tiv thaiv kev tawg.

Cov Ntaub Zoo Li Qub Koob Punched Tsis Yog Woven Npuag

Cov ntsiab cai yooj yim ntawm kev xaws ntaub tsis-woven

Cov ntaub tsis yog woven kuj tseem hu ua Nonwovens, nonwoven, nonwoven, nonwoven lossis nonwoven.

Cov thev naus laus zis tsis yog woven yog ib qho thev naus laus zis ua cov khoom siv uas pib los ntawm textile tab sis dhau ntawm textile. Cov nonwovens sib txawv muaj lawv cov txheej txheem txheej txheem.

Feem ntau, cov ntsiab cai yooj yim ntawm cov thev naus laus zis nonwoven yog sib xws thiab tuaj yeem piav qhia los ntawm nws cov txheej txheem, uas feem ntau tuaj yeem faib ua plaub cov txheej txheem hauv qab no![]() 1) kev npaj fiber; (2) rau hauv lub vas; (3) kev txhawb zog; (4) tom qab ua tiav

1) kev npaj fiber; (2) rau hauv lub vas; (3) kev txhawb zog; (4) tom qab ua tiav

Kev faib tawm ntawm cov ntaub tsis-woven

Cov ntaub tsis-woven tuaj yeem faib ua:

Cov ntaub tsis-woven uas tsis yog-woven

Nws yog lub dav hlau ntawm lub siab siab thiab dej zoo rau ib txheej lossis ntau txheej fiber net, ua rau cov fiber sib xyaw ua ke, ua rau cov fiber net tuaj yeem sib sau ua ke thiab muaj qee lub zog.

Cov yam ntxwv ntawm

Kev sib txuas ua ke yooj ywm, tsis cuam tshuam rau cov yam ntxwv qub ntawm cov fiber, tsis ua rau cov fiber puas tsuaj;

Zoo ib yam li cov ntaub ib txwm muaj;

Muaj zog heev thiab tsis tshua muaj fluff;

Siab hygroscopicity thiab ceev hygroscopicity;

Tes mos, zoo drape

Cov tsos sib txawv;

Cov txheej txheem tsim khoom ntev, thaj chaw hauv pem teb loj;

Cov khoom siv nyuaj thiab cov kev xav tau dej zoo;

Kev siv zog ntau heev.

Daim ntawv thov khoom

Cov ntaub thaiv kev kho mob, khaub ncaws phais, ntaub npog phais, cov ntaub qhwv kho mob, ntaub qhwv qhov txhab, ntaub qhwv kho mob, ntaub plua plav dav hlau, ntaub npog khaub ncaws, ntaub npog hauv paus, ntaub npog txheej, cov ntaub pov tseg, ntaub npog cov cuab yeej siv tshuab, ntaub npog hauv kev lag luam hluav taws xob, phuam da dej, paj rwb pleev kom zoo nkauj, phuam ntub, cov ntaub npog lub ntsej muag, thiab lwm yam.

Cov ntaub tsis-woven uas tau sib txuas nrog cua sov

Nws yog taw tes rau kev koom ua ke cov duab fiber lossis cov hmoov kub yaj hauv cov khoom siv fiber net agglutinate agglutinate, fiber net rov ua kom sov yaj kom txias agglutinate rau hauv daim ntaub.

Cov yam ntxwv ntawm

Qhov chaw nplaum kub dov nto du dua, qhov chaw nplaum kub dov kuj fluffy.

Daim ntawv thov khoom

Kev tsim cov ntaub qhwv menyuam mos thiab cov ntaub so ntswg rau poj niam, cov ntaub pleev tshuaj pleev, cov ntaub nplaum ABD, cov ntaub npog khaub ncaws, daim npog ntsej muag, thiab lwm yam.

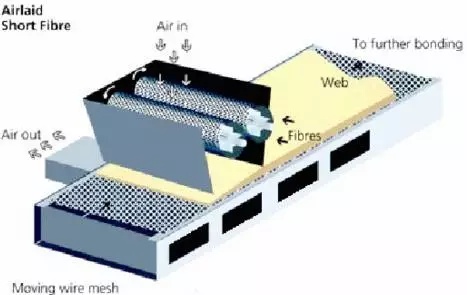

Cov pulp ntws mus rau hauv lub network ntawm cov ntaub tsis-woven

Kuj tseem hu ua daim ntawv tsis muaj plua plav, daim ntawv qhuav tsis-woven daim ntaub. Nws yog siv cov cua nkag mus rau hauv cov thev naus laus zis network kom qhib cov ntoo pulp fiberboard rau hauv ib lub xeev fiber, thiab tom qab ntawd siv txoj kev cua nkag los ua kom cov fiber sib sau ua ke hauv qhov screen, fiber network txhawb nqa rau hauv daim ntaub.

Cov yam ntxwv ntawm

Nws yog tus cwj pwm los ntawm qhov chaw zoo, qhov xav mos, lub zog ntub thiab kev tiv thaiv kev sib txhuam vim yog daim ntawv, cov khoom hygroscopic.

Daim ntawv thov khoom

Cov ntaub ntawv kho mob huv si, tshwj xeeb yog cov khoom siv ntxuav pov tseg uas nqus tau dej zoo (xws li cov ntaub so quav menyuam yaus, cov ntaub so huv, cov khoom noj uas muaj gluten, daim ntaub so, thiab lwm yam).

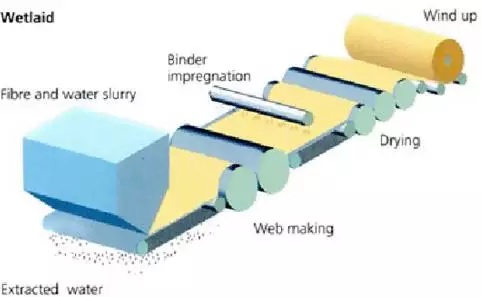

Daim ntaub ntub dej tsis woven

Nws yog kom tshem cov khoom siv fiber ntau hauv cov dej kom tsim tau ib qho fiber, sib tov cov khoom siv fiber ntau tib lub sijhawm, thiab ua cov tshuaj fiber ncua. Cov tshuaj ncua raug thauj mus rau lub tshuab tsim mesh, thiab cov fiber ua lub vas hauv qab lub xeev ntub thiab tom qab ntawd ua kom muaj zog rau hauv daim ntaub.

Cov yam ntxwv ntawm

Kev ceev ceev ntau lawm, txog li 400m / min;

Cov xov luv luv tuaj yeem siv tau tag nrho, xws li qhov ntev tsawg dua 20 hli;

Cov fibers zoo sib txawv xav kom sib tov yuav luag tsis muaj kev txwv;

Qhov sib xws ntawm cov khoom siv fiber ntau yog qhov zoo.

Kev siv dej ntau heev, kev nqis peev ib zaug xwb yog siab.

Daim ntawv thov khoom

Daim ntawv tshwj xeeb: daim ntawv lim hmoov av / kua, hnab tshuaj yej;

Kev siv rau kev lag luam: lim dej, khoom siv rwb thaiv tsev, khoom siv nqus suab;

Kev siv kho mob: kev txhawb nqa kho mob, daim kab xev kho mob, cov ntaub qhwv hnab phais;

Kev siv rau pej xeem: ntawv phab ntsa, thiab lwm yam.

Cov ntaub tsis-woven uas sib txuas ua ke

Tom qab polymer tau raug extruded, ncab thiab tsim cov filament txuas ntxiv, filament tso rau hauv lub network, fiber network tom qab nws tus kheej adhesion, thermal adhesion, tshuaj adhesion lossis mechanical reinforcement method, fiber network rau hauv daim ntaub tsis-woven.

Cov yam ntxwv ntawm

Lub vas sab muaj cov xov txuas ntxiv mus;

Lub zog tensile zoo heev;

Kev siv tshuab hloov pauv ntau dua, tuaj yeem siv ntau txoj hauv kev los txhawb zog;

Qhov ntom ntawm cov xov paj sib txawv ntau heev;

Xav tias pluag dua, qhov sib npaug ntawm cov fiber ntau tsis zoo.

Daim ntawv thov khoom

Polypropylene (PP): geotextiles, cov ntaub pua plag tufted, cov txheej txheej, cov ntaub ntawv kho mob thiab kev noj qab haus huv, cov ntaub ntawv txheej pov tseg, thiab lwm yam.

Polyester (PET): cov khoom siv lim dej, cov khoom siv hauv ob sab hauv, cov ntaub pua plag tufted, cov ntaub ntawv ua liaj ua teb, cov ntaub ntawv ntim khoom, thiab lwm yam.

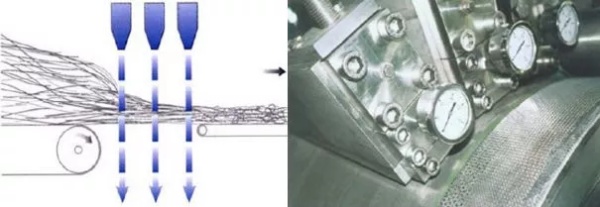

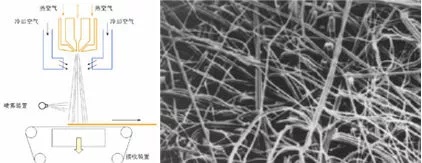

Cov ntaub tsis-woven uas yaj tau

Tom qab cov polymer tau raug extruded thiab tawm hauv qhov spinneret, cov yaj raug cua tshuab mus rau hauv cov fibers ultrafine nyob rau hauv qhov kev ua ntawm cov cua kub ceev, uas ya mus rau lub vas ntawm qhov ceev ntawm extruding ua ke, thiab tom qab ntawd ua cov ntaub tsis-woven los ntawm kev sib txuas thermal lossis kev txhawb nqa tus kheej.

Cov yam ntxwv ntawm

Lub vas muaj cov xov me me, tab sis tsis txuas nrog, luv dua;

Kev sib npaug zoo ntawm cov fiber net, kov mos;

Kev ua tau zoo ntawm kev lim dej thiab kev nqus dej;

Qhov sib txawv ntawm lub zog ntawm cov fiber mesh.

Daim ntawv thov khoom

Cov khoom siv lim dej, cov khoom siv kho mob thiab kev noj qab haus huv, cov khoom siv khaub ncaws, cov khoom siv roj teeb diaphragm, cov khoom siv so.

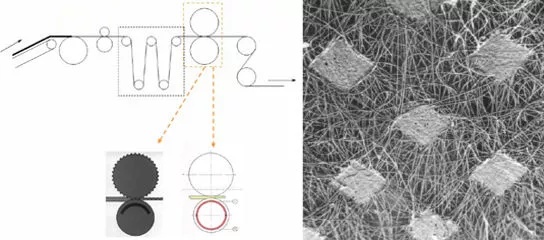

Cov ntaub tsis-woven uas muaj koob

Nws yog ib hom ntaub qhuav uas tsis yog-woven, koob txhaj tshuaj uas tsis yog-woven yog siv cov nyhuv puncture ntawm koob los sib sau ua ke cov fluffy fiber net rau hauv daim ntaub.

Cov yam ntxwv ntawm

Haum rau ntau yam fibers, mechanical postpartum tsis nyob ntawm seb koj xaiv cov yam ntxwv qub;

Cov yam ntxwv qub ntawm cov fiber tsis raug cuam tshuam.

Kev sib txuas ntawm cov fibers nrog kev ruaj khov zoo thiab elasticity;

Kev ua tau zoo ntawm kev pom thiab kev lim dej;

Xav tias plump thiab fluffy;

Raws li qhov yuav tsum tau ua ntawm kev tsim ntau yam qauv sau lossis cov khoom siv molding peb-seem.

Lub sijhawm tshaj tawm: Lub Kaum Hli-18-2019