Abin rufe fuskasu ne masaku marasa saka, waɗanda ba sa sakawa ba sabanin masaku masu sakawa, kuma an haɗa su da zare mai jagora ko kuma bazuwar zare.

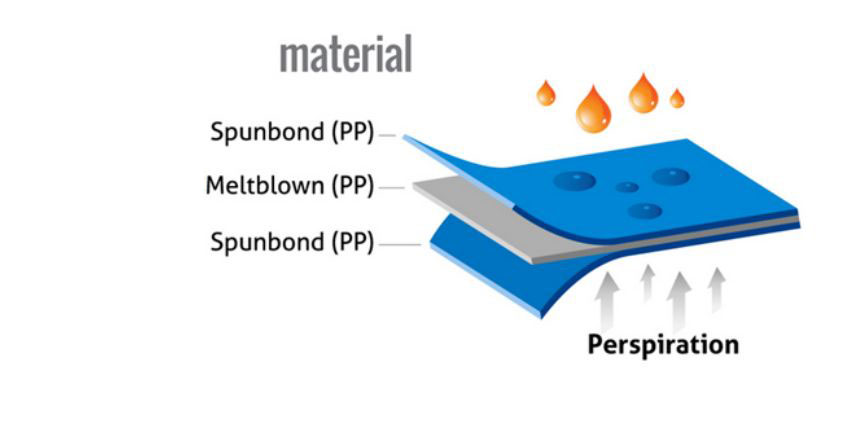

Abin rufe fuska na likitanci galibi tsari ne mai matakai da yawa, wanda aka fi sani da tsarin SMS (tsarin S 2 da M 1). A halin yanzu, mafi girman adadin layuka a China shine 5, wato SMMMS (tsarin S 2 da layukan M 3).

Menene SMS?

A nan, S yana nufin Layer ɗin Spunbond. Diamita na zare yana da kauri sosai, kimanin microns 20 (m). Babban aikin yadudduka 2 na Spunbond shine tallafawa dukkan tsarin yadi mara saƙa, wanda ba shi da wani tasiri mai kyau akan shingen. Mafi mahimmancin ɓangaren abin rufe fuska shine Layer ɗin shinge ko Layer ɗin Meltblown M (Layer ɗin Meltblown). Diamita na Layer ɗin fesa mai narkewa siriri ne, kusan microns 2 (M), don haka kashi ɗaya bisa goma ne kawai na diamita na Layer ɗin spunbonding, wanda ke taka muhimmiyar rawa wajen hana ƙwayoyin cuta da shigar jini.

Abin rufe fuska na likitanci gabaɗaya yawanci ana amfani da zane mai narkewa mai nauyin gram 20, abin rufe fuska na kofin N95 yana amfani da zane mai narkewa mai nauyin gram 40 ko fiye.

A bisa kididdigar da kungiyar masana'antar yadi ta kasar Sin ta fitar, zuwa karshen shekarar 2018, akwai layukan samar da kayan da aka yi da spunbonded guda 1,477 a cikin gida, wadanda suka fi na shekarar da ta gabata yawa, inda aka samu karuwar kashi 65 cikin 100 a shekara, wanda ya kai kashi 4.6 cikin 100, daga cikinsu, layin samar da kayan da ba a saka ba na PP ya karu da kashi 3.38 cikin 100, layin samar da kayan da aka yi da SMS da kusan kashi 13 cikin 100, da kuma layin samar da kayan da ba a saka ba na PET da kashi 9.32 cikin 100. Adadin kamfanonin da ke fitar da kayayyaki a kowace shekara ya wuce tan 50,000 shi ma ya karu daga shekarar 2017. Kamfanonin Spunbonded suna hanzarta ci gaban su zuwa girma, kara karfi da kuma babban mataki don biyan bukatar kasuwa ta inganta kayayyaki da kuma inganta fasaha.

Tun daga shekarar 2018, yawancin kamfanonin cikin gida sun haɓaka samfuransu ta hanyar aiki mai sauƙi, siriri da mafi girma, kuma sun sami sakamako mai kyau. Tsarin haɗakar SSMMS spunbonded/molten shotcreting 600m/min ko sama da haka aiki mai sauri; Kimanin gram 10 a kowace murabba'in mita samfuran haske masu laushi masu ƙarfi suna ci gaba da fitowa.

Daga ina aka samo yadin SMS mara saka?

Yadin da ba a saka ba na SMSAn yi su ne galibi daga polypropylene PP (tare da halayen bacteriostatic na halitta da kuma hydrophobicity), kuma diamita na zare na iya kaiwa microns 0.5-10. Waɗannan zare masu ƙarfi waɗanda ke da capillarity na musamman suna ƙara yawan da faɗin zare a kowane yanki na naúrar, don haka suna sa yadin da aka fesa da narkewa suna da kyawawan kaddarorin tace iska, wanda hakan ya sa su zama kayan rufe fuska masu kyau.

A halin yanzu, akwai manyan hanyoyi guda uku na ƙera kayayyakin SMS (yadin da ba a saka ba na SMS): "tsari mataki ɗaya", "tsari mataki biyu" da kuma "tsari mataki ɗaya da rabi".

Siffofi na mataki ɗaya shine amfani da ɓangaren kayan masarufi na wannan tsari, ta amfani da fasahar da aka haɗa guda biyu, wacce aka narke, kayan da aka juya kai tsaye bayan narkewa cikin raga, matuƙar an tsara su da kyau na tsarin jujjuyawar tsarin, kuma za a iya yin samfuran tare da tsari daban-daban, kowane yadi mai laminated composite, yawanci yana tare da haɗa injin niƙa mai zafi zuwa zane. "Hanyar mataki ɗaya" ana siffanta ta da narkewa kai tsaye yana juyawa cikin raga, yanayin kowane tsarin juyawa ana iya daidaita shi da kansa, tsarin samarwa na iko mai ƙarfi, yanayin lafiya mai kyau, babban gudu, zai iya daidaita rabon kowane Layer na ragar fiber, zai iya samar da samfuran nau'in SMS na takamaiman bayanai daban-daban, shine babban fasaha a yau.

Tsarin matakai biyu: Lokacin amfani da tsarin matakai biyu don samar da samfuran SMS, ana buɗe samfuran da aka gama na zane mai laushi da zane mai narkewa a cikin wani tsari, sannan a laƙaba su a cikin tsari ɗaya, sannan a haɗa su da injin niƙa mai zafi, sannan a haɗa su zuwa samfuran SMS. Hanyar matakai biyu tana da alaƙa da kayan aiki masu sauƙi da ƙarancin farashi. A zahiri, tsarin "mataki biyu" shine fasahar haɗa lamination da ake amfani da ita sosai, amma kuma ana iya haɗa shi da wasu kayan, tare da wasu kayan daban-daban, kuma tare da hanyoyi daban-daban, kamar ultrasonic, manne mai zafi mai narkewa yadudduka uku na kayan tare.

Hanyar mataki ɗaya da rabi: A cikin hanyar matakai biyu, ana iya maye gurbin samfurin zanen feshi mai narkewa da ragar zare mai narkewa da aka samar a cikin filin, ta haka ne aka samo tsarin haɗin gwiwa wanda ake kira "hanyar mataki ɗaya da rabi". Ana amfani da zane mai juyawa azaman layin ƙasa da layin saman ta hanyar na'urori biyu masu sassautawa, kuma ragar zare mai narkewa na tsakiyar ana jujjuya shi kai tsaye zuwa raga ta hanyar tsarin feshi mai narkewa, ana shimfiɗa shi a ƙasan layin zane mai juyawa, sannan a rufe shi da saman layin zane mai juyawa, ya fi kyau a yi amfani da injin niƙa mai zafi wanda aka haɗa cikin samfuran SMS.

Lokacin Saƙo: Satumba-14-2020