Zaren da ba a saka ba wanda aka narke

Hanyar narkewar da aka yi ta hanyar narkewa ita ce hanya ta polymer kai tsaye zuwa cikin hanyar net, ita ce fitar da sikirin fitar da polymer ta hanyar iska mai zafi ko wasu hanyoyi don narke matsanancin tashin hankali da kuma samar da zare mai kyau, sannan a tattara su cikin nadi mai kauri ko labule mai kauri da aka yi a kan hanyar sadarwa ta fiber, a ƙarshe an sami ƙarfin mannewar tasirin tunda ba a saka zaren da aka narke ba.

Ka'idar samar da fiber fusion-jet

1. Kamanceceniya da bambance-bambance da hanyar da aka yi wa spunbonded

Hanyar da aka haɗa da spun

Hakanan an san shi da juyawa kai tsaye zuwa hanyar zane, amfani da hanyoyin juyawa na narkewa kamar sashin polymer ta hanyar narkewar juyawa da kuma samar da ci gaba da filament don hanyar sadarwa, sannan ta hanyar haɗawa, ƙarewa da sauran hanyoyin da aka yi samfuran.

Na gama gari

Dole ne a fitar da polymer ɗin ta hanyar ramin spinneret a cikin yanayin narkewar da aka narke

(2) hanyar sadarwa ta zare na iya zama haɗin zafi (haɗin saman ko haɗin maki) ko haɗin kansa zuwa ƙarfafa masana'anta mara saka

Bambancin B

A cikin hanyar spunbond: iskar sanyi ta kwatsam tana sanyaya, a lokaci guda, tana miƙewa, tana samar da filament mai ci gaba, tana yaɗuwa cikin labulen raga

Hanyar fesawa ta narkewa: fesawar iska mai zafi mai sauri, ta hanyar shimfiɗawa mai tsanani, ƙirƙirar zare mai gajere, a cikin babban gudu don tashi cikin labulen raga ko kuma naɗa raga mai tartsatsi don samar da hanyar sadarwa ta fiber

(2) hanyar spunbond: hanyoyin ƙarfafa hanyar sadarwa ta fiber, ban da haɗin zafi, amma kuma a sha acupuncture, ruwa, haɗin sinadarai da sauran hanyoyi

Hanyar fesawa ta narkewa: galibi ta dogara ne akan haɗin zafi ko haɗin kai

2. Tsarin fasaha na gargajiya

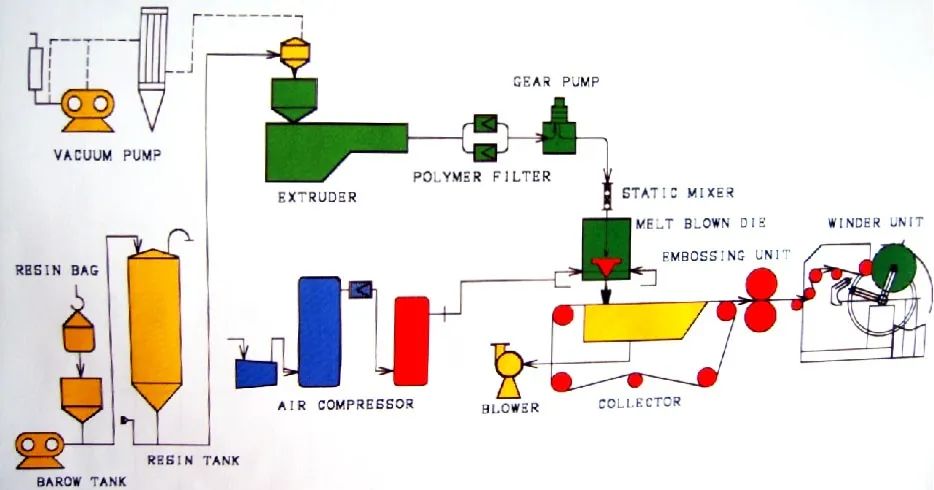

Ciyar da polymer → narkewar narkewa → samuwar fiber → sanyaya fiber → ƙirƙirar raga → haɗawa (raga mai gyarawa) → naɗe gefen yanke → bayan kammalawa ko kammalawa na musamman

Abincin polymer - galibi ana yin polymer zuwa ƙananan yanka masu siffar ƙwallo, masu siffar granular, a zuba su a cikin bokiti ko hopper, sannan a zuba su a cikin wani abin fitar da sukurori.

Extrusion na narkewa -- a ƙarshen ciyar da sukurori, za a haɗa yanki na polymer da mai daidaita, wakilin fari da sauran ƙari, babban ma'aunin launi da sauran kayan masarufi da ake buƙata, bayan an gama haɗa su gaba ɗaya cikin mai fitar da sukurori, a dumama su zuwa narkewa, kuma a ƙarshe za a ciyar da narkewar a cikin spinneret ta hanyar famfon aunawa ta hanyar matatar. A cikin tsarin narkewa da fesawa, mai fitar da gabaɗaya kuma yana rage nauyin ƙwayoyin polymer ta hanyar aikin yankewa da lalata yanayin zafi.

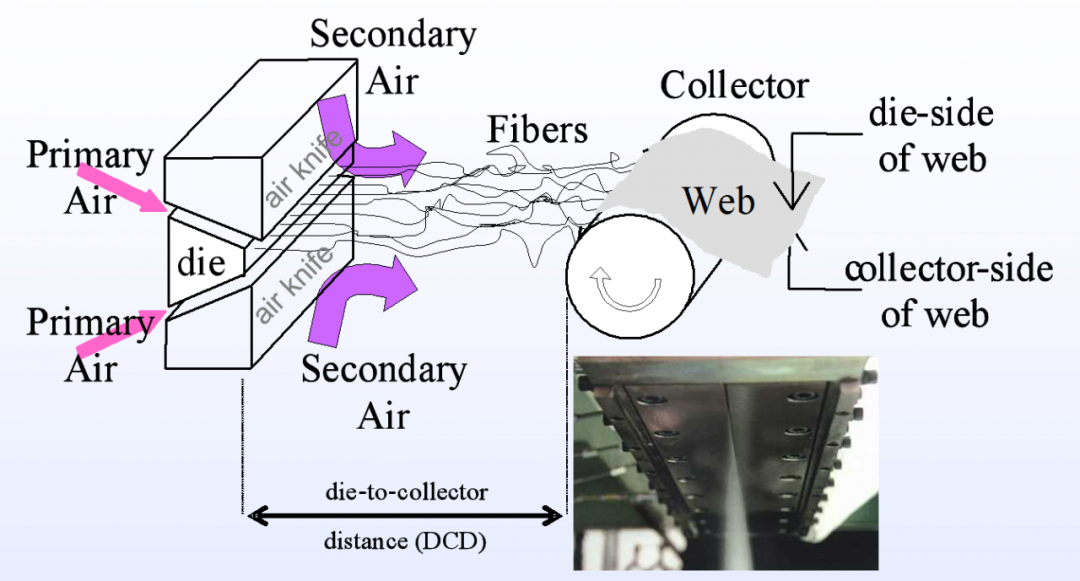

Samar da zare - narkewar da aka tace tana ratsa tsarin rarrabawa kuma ana ciyar da ita daidai gwargwado a cikin kowane saitin spinnerets don samar da adadin fitarwa iri ɗaya ga kowane spinneret. Spinneret na zaren da aka fesa da haɗin kai ya bambanta da sauran hanyoyin juyawa, ramukan spinneret dole ne a shirya su a layi madaidaiciya, ɓangarorin sama da ƙasa suna da ramukan jet.

Sanyaya zare - ana tsotse iska mai yawan zafin ɗaki a ɓangarorin biyu na spinneret sannan a gauraya ta da iska mai zafi da ke ɗauke da microfiber don ta huce. Microfiber ɗin da ke narkewa yana sanyaya kuma yana tauri.

Ramin raga - a cikin samar da zare da ba a saka ba, ana iya sanya spinnerets a kwance ko a tsaye. Idan an sanya su a kwance, ana fesa microfiber ɗin a kan ganga mai zagaye don samar da raga. Idan an sanya su a tsaye, zaren suna faɗuwa akan allon da ke motsi a kwance don samar da raga.

Manne (tsarin sadarwa mai tsayayye) - ƙarfafa manne kai da aka ambata a sama, don wasu dalilai na zanen feshi mai narkewa ya isa, kamar: buƙatun hanyar sadarwa ta fiber yana da tsari mai laushi, kyakkyawan riƙe iska ko rabon void. Kuma ga wasu amfani da yawa, samun damar haɗa kai kaɗai bai isa ba, har yanzu kuna buƙatar haɗa kai mai zafi, haɗa kai ta ultrasonic ko wasu hanyoyin haɓaka. Manne mai zafi

3. Halayen tsari na zare mai narkewa wanda ba a saka ba

(1) gajeriyar hanya, ingantaccen aiki mai yawa;

Zaren yana da kyau sosai, daidaiton raga na fiber yana da kyau, laushi, wajen tacewa, maganin kashe ƙwayoyin cuta, sha yana da fa'idodi masu ban mamaki;

Yanayin fiber ɗin bai yi kyau ba, ƙarfin hanyar sadarwa ta fiber ɗin bai yi ƙasa ba;

Wannan zai cinye makamashi mai yawa.

Babban sigogin tsarin samarwa na narkewa - hanyar fesawa

1. Ma'aunin narkewa (MFI)

Ƙarfi da tsayin daka a lokacin karyewar masakar da aka fesa da haɗin kai sun ragu tare da ƙaruwar MFI. Saboda haka, ana buƙatar MFI na kayan ya zama mai girma gwargwadon iko domin a sami ingantaccen kwararar narkewa a cikin tsarin jigilar iskar gas mai zafi.

2. Gudun kwararar iskar gas mai zafi

A ƙarƙashin yanayin zafi iri ɗaya, saurin sukurori, nisan karɓa da sauran yanayi:

Saurin iska mai zafi ↑ → diamita na zare ↓ → waɗanda ba a saka ba suna jin daga tauri zuwa laushi, tarko na zare yana ƙaruwa, hanyar sadarwa ta zare mai yawa, santsi, ƙarfi ya ƙaru

Amma saurin iska ya yi yawa, furanni masu tashi da sauƙi ba za a iya gani ba, yana da tasiri sosai ga bayyanar zane

3. Kusurwar allurar iska mai zafi

Yana shafar tasirin tensile da kuma yanayin zare

Fasaloli da aikace-aikacen zare mai narkewa (wanda ba a saka ba)

1. Kayan tacewa

Yana amfani da tsarin zare mai kyau sosai, wanda shine farkon kuma mafi girman filin aikace-aikacensa. Bukatar sabbin kayan tacewa kuma shine babban abin da ke haifar da haɓaka zaren da ba a saka ba.

Babu wani ɗan gajeren ulu na matattara da ya faɗi a cikin iskar gas ko ruwa bayan an tace shi da zane mai narkewa.

A halin yanzu, ana amfani da fiye da tan 20,000 na kayan tacewa na narkewa a duniya kowace shekara, kashi 65% na su ana amfani da su don tace ruwa, kamar: tace abin sha da tsaftace abinci, tace ruwa, tace ƙarfe mai daraja, fenti da shafa fenti da sauran tace kayayyakin sinadarai; kashi 35% ana amfani da su don tace iskar gas, kamar: tace iskar cikin gida, tace iska da ruwa, tace ɗakin tsarkakewa.

2. Kayan aikin likita

A halin yanzu, ita ce ta biyu mafi girma a fannin amfani da zane mai narkewa.

A wannan yanki, mafi girman maganin shine maganin tiyata, labulen ɗakin tiyata da kuma zane mai kashe ƙwayoyin cuta, da ƙaramin adadin bandeji mai laushi, tef, da fim ɗin rage kumburi.

3. Kayan tsafta

(1) a cikin adiko na tsafta

★ zane mai narkewa da aka saka a cikin tsakiyar shafa na adiko na goge baki, layin canja wurin capillary

★ amfani da zanen feshi mai narkewa a matsayin shinge ga layin shingen shigar ruwa, tare da yadudduka biyu na zanen feshi mai narkewa maimakon fim ɗin polyethylene mai hana ruwa shiga

(2) dangane da zanen jariri na manya

A yayin aikin samarwa, ana haɗa gajerun zare na ɓangaren litattafan itace cikin kwararar zaren fusiform don samar da wani zane na musamman mai kyau da shan ruwa.

4. Kayan da ke sha mai

A matsayin kayan da ke ɗaukar mai, ƙarfin ɗaukar mai zai iya kaiwa sau 17 fiye da nauyinsa.

Gabaɗaya, ana saka zane mai feshi a cikin dogon bututun raga da aka saƙa daga filament na PET a matsayin grid na ruwa mai iyo don juriya ga mai da kuma sha mai a teku. Hakanan ana iya sanya shi a kan jan ruwa na teku da aka yi da na'urar tattara mai ta hanyar PP, ana ci gaba da tsaftace mai a saman.

5. Kayan tufafi

(1) kayan ɗumi

Mafi kyawun aikace-aikacen shine zane na musamman da aka fesa ta hanyar haɗakarwa da kamfanin 3M ya ƙirƙira a Amurka: a cikin tsarin zaren da aka fesa ta hanyar haɗakarwa, ana haɗa zaren PET don samar da tsarin rufe iska wanda ya ƙunshi zaren PET mai kyau tare da kyakkyawan laushi da zaren PP mai kyau.

(2) tufafin aiki da za a iya zubarwa

Babban amfani da kyallen SMS, ban da gashin aiki, an yi amfani da shi cikin nasara wajen amfani da tufafin kariya a masana'antu.

6, zane mai tsabta

Mafi mahimmanci shine amfani da man PP na halitta, wanda ake amfani da shi don gurɓatar mai a yanayin aiki.

Tare da ci gaban fasahar narkewa da feshi, zane mai narkewa da feshi na PP tare da kayan hydrophilic za a iya yin shi ta hanyar ƙara mai danshi mai kyau, wanda za'a iya amfani da shi a asibitoci, ɗakunan tsarkakewa masu ƙarfi, sassan daidaitacce, kayan aiki da ɗakunan kwamfuta.

Lokacin Saƙo: Afrilu-03-2020