Iifayibha ezingalukwanga ezinyibilikisiweyo

Indlela yokunyibilika ikwayenye ye-polymer ngqo kwindlela ye-net, yi-screw extruder extrusion ye-polymer enyibilikayo ngokusebenzisa umoya ovuthuzayo obushushu obuphezulu okanye ezinye iindlela zokunyibilika ukuxinana okugqithisileyo kunye nokwakheka kwefayibha entle kakhulu, emva koko yaqokelelwa kwi-roller yenethi okanye kwikhethini yenethi eyenziwe kwinethiwekhi yefayibha, ekugqibeleni yenza isiphumo sokunamathela siqiniswe kuba ifayibha enyibilikayo ayilukwanga.

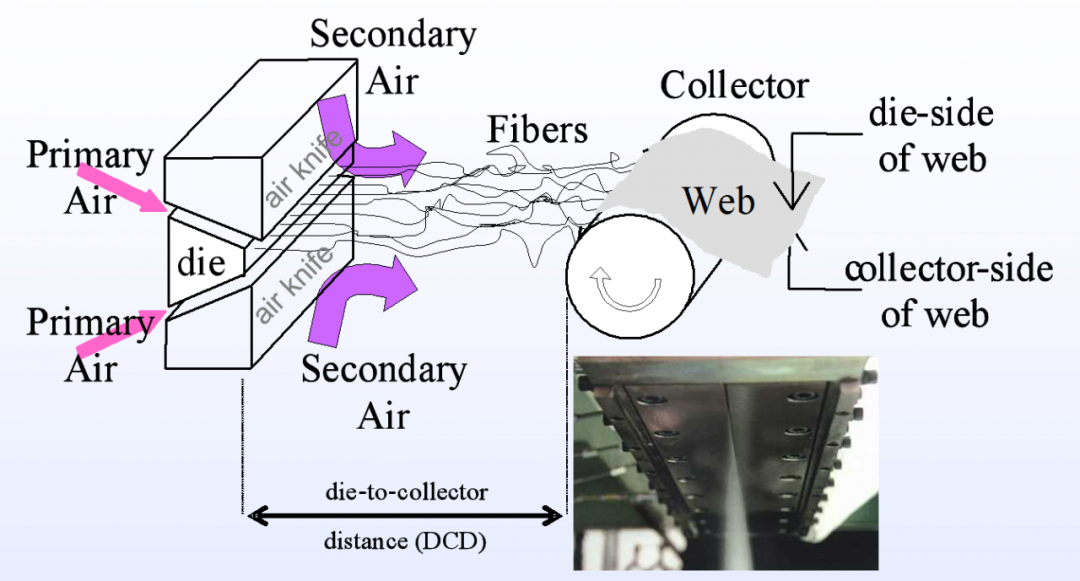

Umgaqo wokwakha i-fusion-jet fiber

1. Ukufana kunye nomahluko kwindlela ye-spunbonded

Indlela edibeneyo

Ikwaziwa nangokuthi yindlela yokujika ngqo ibe yilaphu, kukusetyenziswa kweendlela zokujika ezinyibilikayo ezifana necandelo lepolymer ngokujika ukujiya kunye nokwenziwa kwe-filament eqhubekayo kwinethiwekhi, kwaye emva koko ngokubopha, ukugqiba kunye nezinye iimveliso ezenziweyo.

Isiqhelo

I-polymer kufuneka ikhutshwe ngumngxuma we-spinneret kwimeko enyibilikisiweyo

(2) inethiwekhi yefayibha inokuba yi-thermal bonding (i-surface bonding okanye i-point bonding) okanye i-bonding yayo ibe yi-non-woven texture reinforcement

Umahluko phakathi kwe-B kunye ne-B

Kwindlela ye-spunbond: umoya obandayo ngequbuliso uyaphola, kwangaxeshanye, usolulwe, wenze i-filament eqhubekayo, usasazeke kwikhethini yenethi

Indlela yokutshiza ngokunyibilikisa: ukutshiza komoya oshushu ngesantya esiphezulu, ngokunwebeka kakhulu, ukwakheka kwefayibha emfutshane ethambileyo kakhulu, ngesantya esiphezulu kakhulu ukubhabha ungene kwikhethini yenethi okanye i-condensing net roller ukuze kwenziwe inethiwekhi yefayibha

(2) indlela ye-spunbond: iindlela zokuqinisa inethiwekhi yefayibha, ukongeza kwi-hot bonding, kodwa zikwathatha ne-acupuncture, amanzi, i-chemical bonding kunye nezinye iindlela.

Indlela yokutshiza yokunyibilikisa: ikakhulu ixhomekeke ekubopheni ubushushu okanye ekubopheni ngokwakho

2. Inkqubo yeteknoloji yendabuko

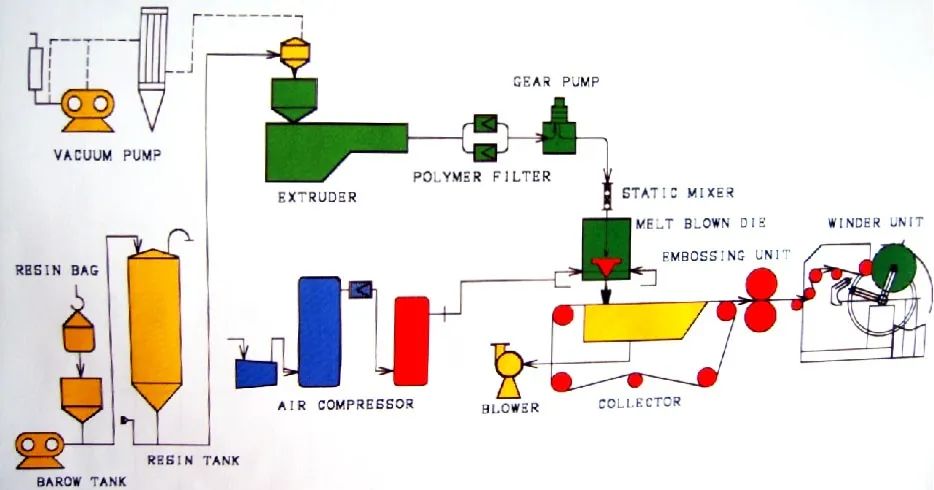

Ukondla ngePolymer → ukunyibilika kwe-extrusion → ukwakheka kwefayibha → ukupholisa ifayibha → ukwakheka kwe-mesh → ukubopha (i-mesh esisigxina) → ukujika komphetho omfutshane → ukugqitywa emva kokugqitywa okanye okukhethekileyo

Ukutya kwepolymer - ipolymer idla ngokwenziwa ibe ziziqwenga ezincinci ezingqukuva, ezigalelwe kwibhakethi okanye kwi-hopper, ize ifakwe kwi-screw extruder

Ukunyibilika kwe-Melt -- ekupheleni kokutya kwe-screw extruder, isilayi se-polymer kufuneka sixutywe ne-stabilizer, i-agent yokwenza mhlophe kunye nezinye izongezo, i-color masterbatch kunye nezinye izinto ezifunekayo, emva kokuxuba ngokupheleleyo kwi-screw extruder, ifudumale ibe yi-melt, kwaye ekugqibeleni i-melt iya kondliwa kwi-spinneret yipompo yokulinganisa nge-filter. Kwinkqubo yokunyibilika nokutshiza, i-general extruder ikwanciphisa ubunzima be-molecular ye-polymer ngesenzo sayo sokucheba kunye nokuwohloka kobushushu.

Ukwakheka kwefayibha - i-filtered clean melt idlula kwinkqubo yokusasazwa kwaye inikwa ngokulinganayo kwiseti nganye yee-spinnerets ukuvelisa inani elifanayo le-extrusion nge-spinneret nganye. I-spinneret yefayibha etshizwe yi-fusion yahlukile kwezinye iindlela zokujikeleza, imingxuma ye-spinneret kufuneka icwangciswe ngomgca othe tye, amacala aphezulu nasezantsi anemingxuma ye-jet.

Ukupholisa ifayibha - umoya omninzi wobushushu begumbi ufunxwa kumacala omabini e-spinneret uze uxutywe nomsinga womoya oshushu oqulethe i-microfiber ukuze uphole. I-microfiber enyibilikisiweyo iyaphola kwaye iqine.

I-Netting - ekuvelisweni kwee-nonwovens ze-fiber eziqhumayo, ii-spinnerets zingabekwa ngokuthe tye okanye ngokuthe nkqo. Ukuba zibekwe ngokuthe tye, i-microfiber itshizwa kwi-drum yokuqokelela ejikelezayo ukuze zenze i-net. Ukuba zibekwe ngokuthe tye, ii-fiber ziwela kwisikrini esihamba ngokuthe tye ukuze zenze i-net.

I-Adhesive (inethiwekhi ezinzileyo) - ukuqinisa okuzincamathelisayo okukhankanyiweyo apha ngasentla, ngeenjongo ezithile zelaphu lokutshiza elinyibilikayo lanele, ezinje: iimfuno zenethiwekhi yefayibha zinesakhiwo esithambileyo, ukugcinwa komoya okuhle okanye umlinganiselo ongenanto. Kwaye kwezinye izinto ezininzi, ukuzidibanisa agglutinate aggrandizement akwanele, kusafuneka i-hot rolling agglutination, i-ultrasonic agglutination okanye ezinye iindlela zokwandisa. Iglue eshushu

3. Iimpawu zenkqubo ye-melt-jet fiber nonwovens

(1) inkqubo emfutshane, ukusebenza kakuhle kwemveliso;

Ifayibha ilungile kakhulu, ukufana kwe-fiber mesh kulungile, kuthambile, kuhluzwa, kulwa neentsholongwane, ukufunxwa kuneenzuzo ezibalaseleyo;

Indlela ifayibha ejongeka ngayo ayilunganga, amandla enethiwekhi yefayibha aphantsi;

Oku kuza kudla amandla amaninzi.

Iiparameter eziphambili zenkqubo yokuvelisa indlela yokutshiza enyibilikayo

1. Isalathisi sokunyibilika (i-MFI)

Amandla kunye nobude xa kuqhekeka ilaphu elitshizwe nge-fusion kwehla ngokwanda kwe-MFI. Ke ngoko, i-MFI yezinto ezikrwada kufuneka ibe phezulu kangangoko ukuze ukuhamba kwe-melt encinci kufumane i-draft engcono kwinkqubo ye-hot gas jet.

2. Isantya sokuhamba kwegesi eshushu

Phantsi kobushushu obufanayo, isantya sesikrufu, umgama wokufumana kunye nezinye iimeko:

Isantya somoya oshushu ↑ → ububanzi befayibha ↓ → Ii-nonwovens zivakala ukusuka kolukhuni ukuya kothambileyo, ii-fiber tangles ziyanda, inethiwekhi yefayibha ixinene, ithambile, amandla anyukile

Kodwa isantya somoya sikhulu kakhulu, kulula ukubonakala njengeentyatyambo ezibhabhayo, nto leyo echaphazela kakhulu inkangeleko yelaphu.

3. I-Angle yenaliti yomoya oshushu

Ichaphazela kakhulu isiphumo sokuxinana kunye nokwakheka kwefayibha

Iimpawu kunye nokusetyenziswa kwe-melt-jet fiber (ilaphu elingalukwanga)

1. Izixhobo zokucoca

ISEBENZISA ikakhulu isakhiwo sayo sefayibha esithambileyo kakhulu, esiyindawo yokuqala neyona inkulu yokusetyenziswa. Imfuno yezinto ezintsha zokucoca ikwayeyona nto iphambili ekuphuhlisweni kwezinto ezingasebenziyo zefayibha ezinyibilikisiweyo.

Akukho boya bufutshane bezinto zokucoca eziwela kwigesi ecociweyo okanye kulwelo emva kokuhluzwa ngelaphu lokutshiza elinyibilikisiweyo.

Okwangoku, ngaphezulu kweetoni ezingama-20,000 zezinto zokucoca i-melt-jet zisetyenziswa ehlabathini minyaka le, ezingama-65% zazo zisetyenziselwa ukucoca ulwelo, ezinje: ukucoca iziselo kunye nococeko lokutya, ukucoca amanzi, ukucoca isinyithi esixabisekileyo, ipeyinti kunye neengubo kunye nezinye iimveliso zeekhemikhali; ama-35% asetyenziselwa ukucoca igesi, ezinje: ukucoca umoya opholileyo ngaphakathi, ukucoca umoya kunye namanzi, ukucoca igumbi lokucoca.

2. Izixhobo zonyango

Okwangoku, le yindawo yesibini ngobukhulu yokusebenzisa ilaphu lokutshiza elinyibilikayo.

Kule ndawo, idosi enkulu yibhandishi yotyando, amakhethini egumbi lokutyanda kunye nelaphu lokutyanda lokubulala iintsholongwane, kunye nenani elincinci lebhandishi elastiki, iteyiphu, ifilimu yokuthomalalisa iintlungu elwa nokuvuvukala.

3. Izinto zokucoca

(1) kwiinapkin zococeko

★ ilaphu lokutshiza elinyibilikisiweyo lifakwe kwisiseko sokufunxa se-napkin yococeko, umaleko wokudlulisa i-capillary

★ ukusetyenziswa kwelaphu lokutshiza elinyibilikayo njengesithintelo kumaleko wokuthintela ukungena kolwelo, kunye neeleya ezimbini zelaphu lokutshiza elinyibilikayo endaweni yefilimu engangenisi manzi ye-polyethylene

(2) ngokubhekiselele kwiinapukeni zabantu abadala

Kwinkqubo yokuvelisa, iifayibha ezimfutshane zepulp yomthi zixutywa kwi-flow yefayibha ye-fusiform ukuze zenze ilaphu elikhethekileyo le-fusiform elifunxa kakuhle.

4. Izinto ezifunxa ioyile

Njengezinto ezifunxa ioyile, amandla okufunxa ioyile anokufikelela kubunzima obuphindwe kalishumi elinesixhenxe.

Ngokubanzi, ilaphu lokutshiza elifuthayo lifakwa kwityhubhu ende enemingxuma ethungwe nge-PET filament njengegridi yamanzi edadayo yokumelana neoyile kunye nokufunxwa kweoyile elwandle. Lingafakwa entlokweni yodonga lolwandle olwenziwe ngesixhobo sokuqokelela ioyile yelaphu lokutshiza elinyibilikayo le-PP, ukucoca ioyile rhoqo phezu komphezulu.

5. Izinto zokunxiba

(1) izinto ezifudumeleyo

Eyona ndlela iphumelele kakhulu yindlela ekhethekileyo yokufutha ilaphu elikhethekileyo eliphuhliswe yinkampani ye-3M eMelika: kwinkqubo yokufutha ifayibha ephuhliweyo, ifayibha ye-PET staple ixutywa ukwenza isakhiwo sokukhusela umoya esakhiwe yifayibha ye-PET staple enokuguquguquka okuhle kunye nefayibha ye-PP ultrafine.

(2) impahla yabasebenzi elahlwayo

Ukusetyenziswa okuphambili kwelaphu le-SMS elidityanisiweyo, ukongeza kwi-operating coat, kusetyenziswe ngempumelelo kwiimpahla zokuzikhusela kwimizi-mveliso.

6, ilaphu elicocekileyo

Ngokuyintloko kukusetyenziswa kwe-PP yokufunxwa kweoyile yendalo, iintlobo ngeentlobo zeoyile ezisetyenziselwa ungcoliseko lwendalo kwindawo yokusebenza.

Ngokuhambela phambili kwetekhnoloji yokucubungula ukunyibilika nokutshiza, ilaphu lokunyibilika nokutshiza le-PP elinophawu lwe-hydrophilic linokwenziwa ngesongezo esifanelekileyo sokufumisa, esinokusetyenziswa kwizibhedlele, kumagumbi okucoca aphezulu, kwiindawo ezichanekileyo, kwizixhobo nakwimagumbi eekhompyutha.

Ixesha lokuthumela: Epreli-03-2020